ICOMPOST SUPER PLUS

𝗢𝗿𝗴𝗮𝗻𝗶𝗰 𝗪𝗮𝘀𝘁𝗲 𝗖𝗼𝗺𝗽𝗼𝘀𝘁𝗲𝗿

ECOFRIEND(S) works on principle of aerobic composting by following three step processes.: Shredding, Dewatering & Curing

icompost– Ecofriend can reduce 50 % of volume following these steps and will make quality compost with good amount of nutritional value which can be marketable. Icompost – Ecofriend is a balanced & open-architecture model to reduce cost of machine and allow advance aerobic composting process. The body of Icompost – Ecofriend is of stainless steel or MS sheet with hot dip galvanizing to provide a long service life and reduce corrosion. ECOFRIEND includes automated auger mixing systems with positive aeration and ventilation systems for odour control.

How it Will Work

Icompost – Eco friend can be operated as either batch or a continuous flow composting systems:

Batch Process: The system is fully loaded with material. These materials are composted as a batch and then fully discharged.

This approach works well for materials such as:

- agro waste,

- cow dunk

- horticulture waste

Flow Process

It's start with Pair where Two material holding tanks are will be used for daily generated waste with approx 25 days of curing.

One need to fill the first tank which allows to feed daily waste from up till 20 days . there after second tank will be in use for feeding waste for another 20 days.

Mixing system will operate automatically every 3 hours in a day. First batch of compost will be ready on 40th day from the date of first input. Second and other continue batch's of compost will be ready within 3 weeks. During this batch process Advance aerobic composting technology which convert waste in to compost within 20 days with high nutrition value through micro organisms based composting method.

Shubham inc, manufacturer,exporter,trader,supplier of all type of sewage treatment plants, effluent treatment plants, India best quality sewage treatment plants manufacturers from Ahmedabad, send requirement detail of sewage treatment plants, effluent treatment plants etc.

Features & Benefits

Icompost – Ecofriend has integrated mixing system that allows the compost to be mixed on a daily basis (2-3 hours per day). Mixing system technology provides optimum conditions for food waste composting with six distinct operating functions:

- Superior Compost Quality –extremely rich, light, homogeneous, oxygenated compost.

- Cost Effectiveness – For its size and capability, Icompost – Ecofriend is the most cost effective aerobic composting system .

- Small Footprint – When space is restricted, Icompost – Ecofriend is ideal and very modest footprint.

- Complete Control – icompost– Ecofriend gives you complete control of your composting process, allowing you to control temperature, moisture content by adjusting patterns for mixing, aeration and moisture addition.

Shubham inc - A Water and Waste Water Management Company

Phone: +91-7940086151 | +91-9099941306

Email : info@shubhamindia.com

Web: www.shubhamindia.com

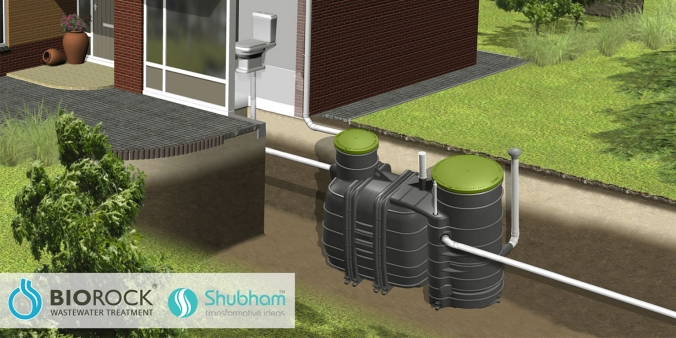

Apart from public health and pollution norms, STP facilities has also becoming new source of water which can be used for irrigation, horticulture, industrial and many other non-potable purpose. Recycling of sewage treated water directly reduce consumption of fresh water and help to come out from water scarcity problem.

Sewage treatment is the process of removing contaminants from domestic wastewater called “Sewage” coming from various part of city and inhabitant area, which includes physical, chemical and biological processes to produce an environmentally safe fluid waste stream (or treated effluent) and a solid waste (or treated sludge) suitable for disposal or reuse (usually as farm fertilizer).

Various technologies from Oxidation pond to Activated sludge process and advance MBBR to MBR process has been adopted by municipal and government bodies to provide effective treatment of domestic sewage water depending upon the uses of treated sewage water which formulate as

Apart from public health and pollution norms, STP facilities has also becoming new source of water which can be used for irrigation, horticulture, industrial and many other non-potable purpose. Recycling of sewage treated water directly reduce consumption of fresh water and help to come out from water scarcity problem.

Sewage treatment is the process of removing contaminants from domestic wastewater called “Sewage” coming from various part of city and inhabitant area, which includes physical, chemical and biological processes to produce an environmentally safe fluid waste stream (or treated effluent) and a solid waste (or treated sludge) suitable for disposal or reuse (usually as farm fertilizer).

Various technologies from Oxidation pond to Activated sludge process and advance MBBR to MBR process has been adopted by municipal and government bodies to provide effective treatment of domestic sewage water depending upon the uses of treated sewage water which formulate as